Arctic Cat is a company loaded with talented, creative, passionate and hard working engineers. In the Snowmobile department, Doug Braswell is the person tasked with directing that amazing engineering workforce to produce the best snowmobiles in the world, and that carry on the tradition of a brand that’s 54 years old.

At the tender young age of 55, Braswell comes to his role as Director of Snowmobile Engineering with a long list of experience at Arctic Cat as well as John Deere. He might be a farm kid from rural Missouri, but Braswell is smart and savvy professional whose passion for snowmobiles is as deep as it is wide. The married father of two was gracious enough to answer key questions about his role, how he’s organized the department and some clues to what we can expect for future product.

AI: Let’s start by telling us what your current role is at Arctic Cat with a nutshell description of what you’re responsible for.

Braswell: I am currently the Director of Engineering – Snowmobile. I am asked often what my roles and responsibilities entail – and the best analogy of my job is that I am the Coach of a Professional team. I’ve trained, I’ve played, I understand what it takes to execute on the field to win, and I know the importance of having well prepared leaders and a strong team members to achieve the success of a high performing organization.

AI: Is it your job to set strategic goals for engineering, or to tactical ones? For instance, do you make the decision of what kind of snowmobiles Arctic Cat will produce in 5 years, or do you make the decision of how Engineering will achieve the snowmobiles that others are asking for?

Braswell: Yes, I provide visionary guidance for developing the strategic goals for the engineering department. Those goals include many things that support the product plan for future snowmobiles. Personnel, budgeting, training, & developing efficiencies are just a few. A cross-functional group that is focused on satisfying our customers develops our product plan. I am involved from time to time on the tactical decisions, as staying grounded with the folks that are developing our next offering of snowmobiles is very important to me.

AI: Is Arctic Cat an Engineering-driven company, a Marketing-driven company, or both?

Braswell: Arctic Cat is a customer driven company! I am a bit partial to saying that we are an engineering company, but we work in great partnership with marketing. And our engineers enjoy being part of the narrative that marketing uses to explain our machines. We are a company full of passionate, creative people who have great ideas and influence in many areas of the company.

AI: You’ve had an interesting 2-stage career at Arctic Cat. Run us through the various roles you’ve had, and your time away from Cat.

Braswell: My first tour of duty with Arctic Cat had me starting out working for Ole Tweet (who still one of my hero’s here) in the New Product Development group – Tigershark’s and the ATV were my first vehicles to work on. My main responsibility was accessory engineering.

Next I was involved in ATV powertrain development, testing, and validation. My testing background always had me “looking over the fence” at snowmobiles, and Roger and Ole agreed that we needed to focus on data acquisition – using field data to make design decisions and reduce the amount of time needed to test in the field.

From my data collection work, I really became involved in developing snowmobile suspension systems. I eventually worked with Kirk Hibbert on the performance sled suspension and my final assignment at Arctic was the manager of the High Performance snowmobile team.

I left Arctic Cat for John Deere in 2004. One of the toughest decisions I had ever made in my life was to leave Arctic Cat. At Deere I was involved in Product Support, Product design, Manufacturing, Marketing, Testing, and Management. I attribute much of my success at Deere to the teaching and work ethic that was instilled in me from my time at Arctic Cat. Deere provide the opportunity to achieve the equivalent of an MBA and PhD in how big business operates – from the management of people to the building of machines that move 50 tons of dirt.

AI: From a 40,000 foot view, what are some similarities and differences between Arctic Cat and Deere?

Braswell: In terms of similarities, both companies enjoy EXTREMELY loyal customers.

Differences: Annual revenue (laughter). Deere is a massive, global company with enormous budgets. Their financial strength makes possible certain opportunities and growth that’s very different than what’s available to mid-sized companies like Arctic Cat.

AI: When you started your current job, what were your goals and what were you looking to change or modify in terms of how Engineering operated?

Braswell: When I started my second tour with Arctic Cat, I developed a 30-60-90-180 day plan that I shared with my boss Brad Darling for his input and approval. As with any new job, and especially a leadership role, you must learn as much as possible about your new team. I spent time conducting one on one’s with each of the engineers to understand what was working well and what we could do better. From those interviews and observations, we put a plan into place to organize the engineering teams that deliver higher efficiencies in development methods and shorten the time required in product development. Teams were reinforced with new team members, and we are in the process of implementing a new Product Development Process that will make us even better.

Arctic Cat customers will see some of these changes in 2017, and even more in 2018. These are exciting times for the snowmobile engineering department.

AI: One of the first big changes you made was to create an advanced engineering group, a Skunk Works of sorts. Can you talk a bit about that?

Braswell: Advanced R&D is a part of the business that is key to creating new technologies and products that our customers do not yet know they need or want. The company has realized value by establishing a true R&D group and the ideas that will be placed in future sleds. I have some really creative guys in the group. Their names cannot be revealed due to the secrecy of the projects.

I really wish I could tell you more about the 5 cylinder radial piston, five valve, overhead push rod two stroke engine that is powering the 375 pound unobtainium sled that we are testing!It has a 181-in. track and…that’s all I can say for now (laughs).

AI: Here’s my down payment on that (laughs). In all seriousness though, have we yet seen any fruits from the advanced R&D effort?

Braswell: Nothing that can be published or discussed until model year 2017.

AI: Snowmobilers, myself included, want a consistent stream of new technology, every year. New engines, suspensions, chassis…new technology everywhere. I know it’s not possible, or should I say reasonable, for that to happen every year. What are the hurdles to introducing lots of new technology on a yearly basis?

Braswell: We are focusing on developing year round methods of testing so that we can provide a continual stream of new technologies. Sub-zero temperatures and plenty of snow to simulate real world conditions are on the horizon for AC.

AI: Are there more barriers to introducing new technology now than there were 10 or 20 years ago?

Braswell: The complexity of conducting business is much greater than in the past. Technology is much easier to capture today due to the electronic tools we have at our disposal. However, incorporating some of the most cutting edge and exciting technology is difficult because of the relatively low volumes of the snowmobile industry.

For instance, we as snowmobilers want the same kind of lighting or electronics/navigation technology as our trucks. While snowmobile technology is catching up with automobiles, the problem is that because of the low volume of sled industry, the costs skyrocket. Anything less than 100,000 units is seen as a distraction for companies that provide some of this technology. That’s a challenge for us and our customers.

AI: On the flipside, there are new tools and processes for creating new technology now that didn’t exist a decade or two ago. What are some that Arctic Cat uses?

Braswell: We are advancing our abilities in adaptive manufacturing as well as rapid prototyping in plastics, which allow us to go from concept to creation in a fraction of the time it used to take.

For instance, today an engineer can brainstorm and draw a new shape for an air intake system on a snowmobile, have it printed overnight, then test it on a snowmobile the next day, saving weeks and even months over the previous era.

AI: Describe the balance, or interaction, of engineering by high-tech tools such as computers, 3D printers and data acquisition, compared to engineering by a guy doing a quick fab job in the shop.

Braswell: We have an equal balance of both taking place. We still spend plenty of time building proofs-of-concepts, however, with today’s advancements in technology, those proofs-of-concepts take only a matter of days to produce. Ten years ago they required a few weeks.

AI: How will Arctic Cat Engineering be different in 10 years than it is today?

Braswell: Our development processes will be streamlined; not all resources will be sitting in TRF; and opportunities of combined synergies of similar functions will be at higher level between snow and dirt engineering.

AI: Whoa, that’s some pretty hefty changes. What do you mean and/or can you give an example?

Braswell: Well, it means we could have certain departments located in different parts of the state, or country or even the world, which would diversify our design capabilities and talents.

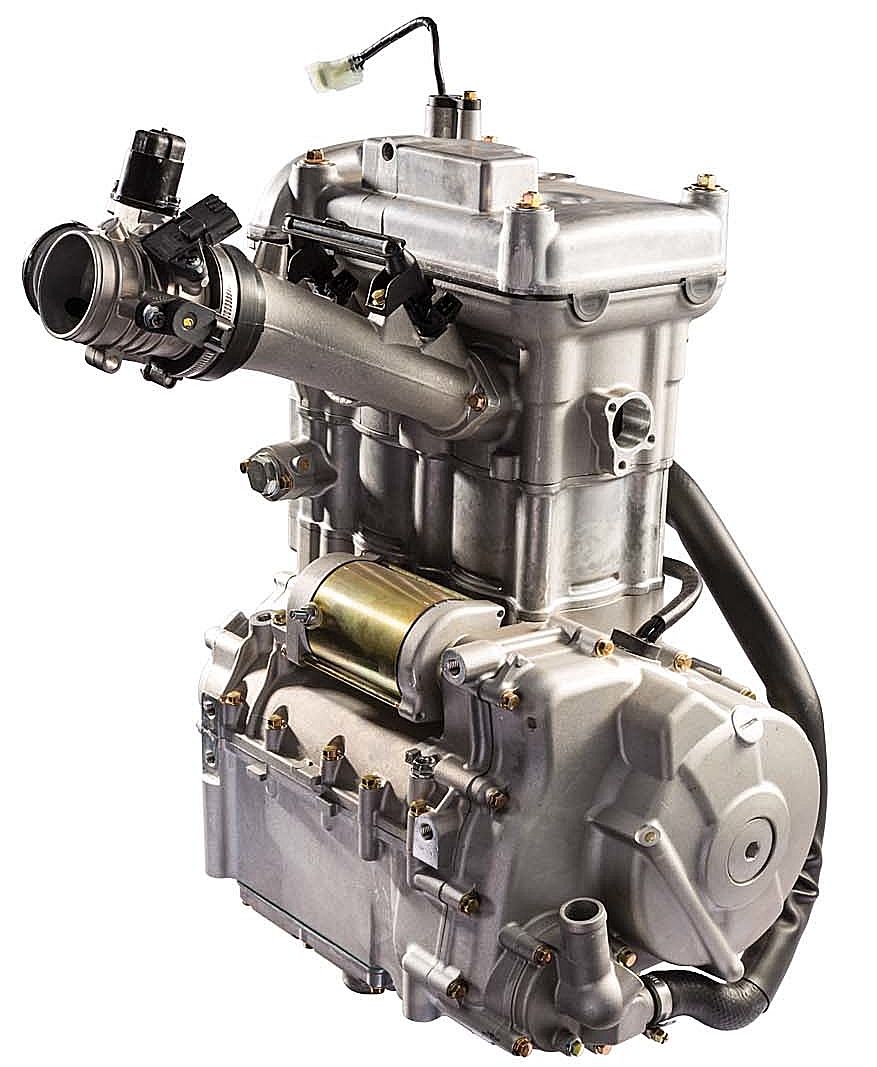

As for combined synergies between snow and dirt engineering, you could see shared 4-stroke engines, the first example of which is the 700 twin (above) that debuted in the Wildcat Trail and is now in Pantera and Bearcat models. Eventually we’re going to have adaptive ride control on all of our vehicles. We will approach some of these technologies together, to speed development while reducing costs.

AI: Arctic Cat has a long history of building some of the most badass hotrod snowmobiles of all time. Is that an important legacy that should be maintained in the future?

Braswell: No doubt Arctic Cat has provided snowmobilers with many great Hot Rods that made the competitors look for their blankie and teddy bear to go and hide with. We will continue to push the performance standards in all areas and enjoy our successes on and off the track. Stay tuned. The twister through the trailer park is near! Ha!

AI: Does it matter any more to have the fastest 800 or 600?

Braswell: I believe the industry has evolved that being fastest isn’t the most important feature of a snowmobile. People are looking for higher levels of quality, reliability, durability and comfort. Of course, snowmobiles have to have high performance. They have to hit you on an emotional level. And they have to be have relatively similar performance as other machines. Being well built and reliable is as important as being two sled lengths ahead at the end of the lake.

AI: What is, and what should be, the role of racing in the development of snowmobiles?

Braswell: I am fortunate to have Brian Dick on my leadership team. Not only is Brian keen on keeping Arctic Cat in the fast lane with our performance sleds, he also uses the race sleds to push the limits for future designs. Snocross indeed is a test bed for “maximum impact” to critical parts and cross-country provides the accelerated test lab environment approach to proving our durability. Racing will continue to play a very important role in my organization.

AI: There has been a huge push for improved quality in recent years. What are some examples of this effort in the Engineering department?

Braswell: The introduction of the TEAM clutch system. It is no secret we had clutch problems for a few years. It is fair to say the TEAM clutch system brings a legend of racing success to the table. Kevin Thompson’s drive group spent two years developing the new TEAM CVT system – and they have done a great job in bring the next level of quality to our snowmobiles. We have also been fortunate to have partnered with Yamaha, who no doubt is a leader in quality. The partnership has provided Arctic Cat with processes that have served both companies very well. Arctic Cat builds very high quality snowmobiles today, and they will be even better in the future.

AI: Okay, I’m going to lighten up the questions a bit. What’s your all-time favorite snowmobile?

Braswell: I have several: the first Crossfire that Joey Hallstrom and I developed; the John Deere 440 Trailfire (long live Horicon! – stop number four for me while at Deere); and a ZR 440 with a 136” long track kit. Plus there were some prototypes that were developed with Aaron Scheele and Jason Howell that I really enjoyed.

AI: Who’s more passionate and loyal, an Arctic Cat or John Deere fan?

Braswell: Arctic Cat fans are the most passionate. John Deere fans are the most loyal.

Both customers love their machines. It’s good they are both green! (Laughs)

AI: If you could own only one Arctic Cat snowmobile, which one would you pick?

Braswell: The one that we have not yet developed.

AI: That’s a very Roger Skime-like answer. Are you a 2-stroke or 4-stroke guy?

Braswell: A 4-stroke on the trail…Yamaha builds smooth and powerful 4-stroke engines.

For mountain riding I want an Arctic Cat 2-stroke! Arctic Cat’s two stroke engine group builds an amazing 600!

AI: How much riding do you get in during a normal winter?

Braswell: Never enough. Every day is the goal when there is snow on the ground. On the weekends I am glad if it is ten miles or 200 miles. I learned from Roger Skime that there is no replacement for seat time.

AI: Okay, that’s a good segue, so let’s wrap this up with you telling us a Roger Skime story.

Braswell: Roger means a lot to me. I learned a lot personally and professionally from working for him. On my 3rd day of work at Arctic Cat, I was walking down the hallway and here comes Roger, on his way to the assembly line to check on something. As I get closer, I stuck out my hand, introduced myself and told him one day I would work for him. He smiled and said that was good. Time passes and less than 10 years later, Roger had a farm guy from Missouri managing his high performance team. Fast-forward another 10 years… WOW the trip has been amazing!

AI: That’s cool, thanks for sharing all your insight Doug.

Braswell: You’re welcome, it was fun.

Another major asset along with many many more in TRF that what makes Arctic Cat what it is today. Thanks again John for another Insider factory write up, and this has to be one of the best slogan’s and can’t stop laughing……….”Stay tuned.The twister through the trailer park is near! Ha!”

Agreed, “Stay tuned. The twister through the trailer park is near!”

Awesome! That made me giddy!!

That needs to be an AC advertisement.

Wow! Absolutely wow! I had already started to believe that the Arctic Cat brand is poised for a giant leap forward, and reading an interview like this one only reinforces that 100-times over! Us Arctic Cat fans are in for one heckuva ride…this is going to be fun!

Articles like this make me happy to be a die hard Cat guy! I finally convinced my wife to make a trip out west for vacation, and we are swinging by TRF for the factory tour…on HER birthday!

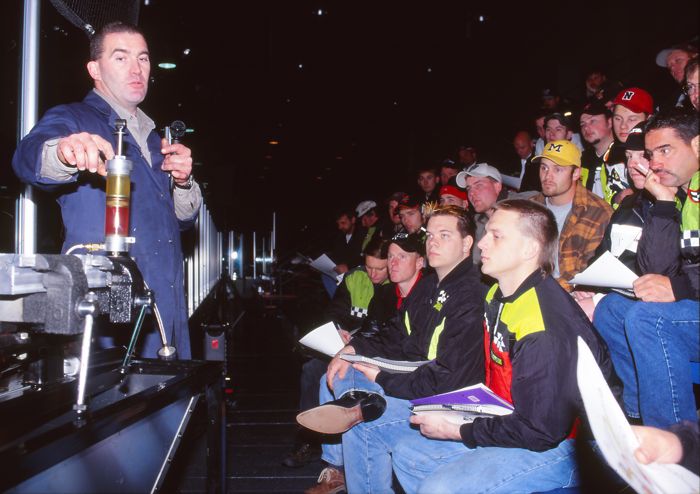

I remember the seminar at the 2001 race school going over the cross-link… And there is my Brother Jon and I, front row next to Mr. Braswell!… It’s a crime to think I used to frost my hair!

This article is very interesting. I am glad to see that Mr. Braswell is back at Arctic… Say what you will about the cross-link suspension… Admittedly; I thought it was not durable enough to be used on even our race sleds! However, the concept of it was so amazing and that cutting edge development is what separated Cat from everyone else in my mind.

Cat fans are blessed to have someone like him lead new technologies for future product development and this was a great interview to read. I look forward to 2017 and beyond.

i agree that being fastest doesn’t matter and that quality is more imprortant. but please continue to make the fastest sleds anyways!

My brother is freestyling a ZL with Smart Ride rear suspension this season. Any tips on valving it for backflips?

Bobby Flame, take 4 quarter’s, 3 nickel’s and 2 dimes and drill a 3/8″ hole through all of them and install in that order on the compression side of piston. Next take 1 quarter, 1 nickle and 1 dime and drill another 3/8″ hole and install them in the same order on the rebound side of the piston and your brother should be good to go.

Scott Watters… You joke, but I found 31 cents in the chain case of a 1978 6000 El Tigre once; quarter, nickle, and penny – no holes in them. I had driven it 10 or so miles before I tore it apart. I think the guy that had it before me took your advice!

(Great article. I would argue, for pure content, Insider’s best work yet)

Hey Doug,

Come on over and drive my shiny new John Deere lawn tractor.

You will be happy to hear I now ride a Cat. Yeah I was a slow learner.

Say hi to your wife from me. I hear she is still down in Missouri.

Speaking as someone who has driven a restored 1980 JD 440 Trailfire hard down a groomed fire road, yes, that sled is STILL great fun. It rode so well I had to check to make sure I was riding a leafer. For carving corners it was the equal of the 1980 5000 El-Tigre, and it was lighter. The engine was tame, but adequate for the intended use. I can’t help but wonder what would have happened had they made this a longer travel IFS design.